Temperature Metrology

Examples for our production processes and methods

JAKO operates its own special machine construction departement to make sure that JAKO measuring instruments meet the highest quality and performance requirements and can be cost-effectively produced.The example of bimetal thermometers gives you some insight into our different production methods and facilities.

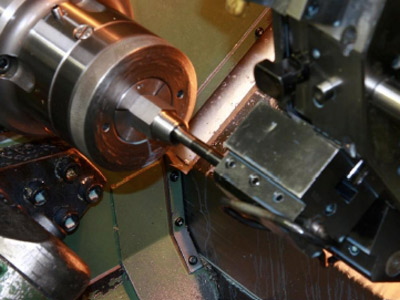

One-piece thermowells, shaft designs, base pieces

Drilling, turning, milling, cutting

|

|

Surface treatments

Slide grinding, vibratory grinding, degreasing, washing

|

|

|

Designs in bimetal

Punching, coiling, turning of base pieces, spot welding of sindels

|

|

|

Housing and measuring sensor joints

Joining methods – manual and semi-automatic

|

|

|

Assembly of standard bimetal thermometers

Manual and semi-automatic

|

|

|

Customized dial inscriptions for OEM customers and partners

TEXT, LOGO or GRAPHICS inscription

|

|

|

Industrial thermometer assembly

Assembling – manual and semi-automatic

|

|

|

Thermometer test rig

Intermediate and final tests

|

|

|

Thermowell production

Manual and semi-automatic

|

|

|

Thermometer adjustment & final control

Logging and calibration

|

|

|